IN SITU NiS GLASS INSPECTION

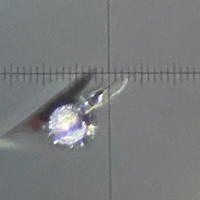

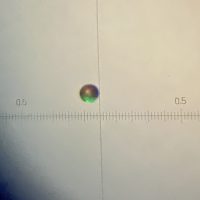

In Situ inspection method for detecting NiS inclusions in toughened glass panels.

Nickel Sulphide (NiS) inclusions are a known issue for toughened glass, they are the major cause of spontaneous failure and remain a global issue, with the problem not restricted to any one manufacturer. NiS inclusions have been found to be the cause in over 60% of panel failure cases, while other motives include poor installation practices and external forces (impact).

NiS inclusions are a result of nickel contaminants present in the glass melt process reacting with sulphur, most likely from the furnace fuel or additives to reduce the formation of air bubbles. During thermal toughening these inclusions undergo a crystalline phase change to a smaller form and upon cooling are fixed in place within the glass. Over time the inclusions grow, and if they are located in the tensile zone (central section) of the heat-soaked glass they can eventually impart enough stress to cause spontaneous failure.

Most panels containing the impurities will break in the first 2 – 7 years, however there have been examples of panels breaking after more than 10 years. NiS inclusions are an ongoing concern with major glass manufacturers and engineers aware of projects where such failures have occurred in the past two decades.

The method commonly used to reduce the occurrence of the inclusions is a heat soaking method carried out in the factory following manufacture of the units however, even this process is only 95% reliable. Despite these measures to reduce or eliminate the problem manufacturers are unable to guarantee NiS free glass or give guarantees that such breakages will not occur in Heat Soak tested or Heat Strengthened glass. Consequently Nickel Sulphide (NiS) induced failure in toughened (fully tempered) glass continues to occur in buildings around the world and NiS inclusions remain a current issue facing all building designers as to the appropriate action required in order to minimise this risk of panel failure.

The risk of injury to the public as a consequence of NiS induced failures in toughened glass is a constant threat to building owners and managers. Litigation as a consequence of NiS induced failures in buildings has made the wider industry aware of the problem. The associated costs of litigation are a serious matter and should be of concern to all involved with the use of toughened glass in buildings.

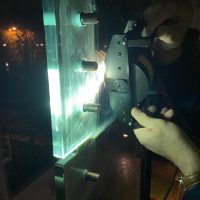

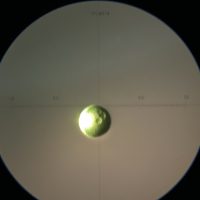

RAI offer a service for the in situ testing of toughened glass units to locate and identify any critical NiS inclusions to be found within the unit.

We also offer a service for the removal and replacement of any units where the presence of critical NiS inclusions is confirmed.

Contact Us

For further information on our Rope Access Services, contact RAI SG Solutions on +61 0409 874 747 or get in touch via the button below.

Our Accreditations